CAPABILITES

Our shop runs several Star Swiss machines. Each machine is capable of producing high quality parts in a variety of materials.

Machines in Operation

SA-16 up to 5/8'' bar stock

SB-16 up to 5/8'' bar stock

SR20R up to 3/4'' bar stock

SR20RII (x2) up to 3/4'' bar stock

SR20RIII 2014 up to 3/4'' bar stock

SR32 up to 1.25'' bar stock

SR32J up to 1.25'' bar stock

SB20RG 2018 up to 3/4" bar stock

SB20RG 2021 up to 3/4" bar stock

Drilling, Turning, Milling, Boring, Knurling, Threading– each of these functions can be performed in a single operation to produce a complex part.

- Machining up to 32mm material diameter

- Paired with an automated 12’ bar loader

- Round, Square, or Hex shaped material

- Deep hole drilling

- Carbon Steel 1018, 1045, 1117, 12L14, and 1215

- Stainless Steel 303, 304, 316, and 17-4

- Aluminum 2011, 6061, and 7075

- Alloy Steel 4140, 8620, and 52100

- Brass, Bronze 954, Copper

- Tool Steel A-2, O-1

- Titanium

- Assorted Plastics

QUALITY

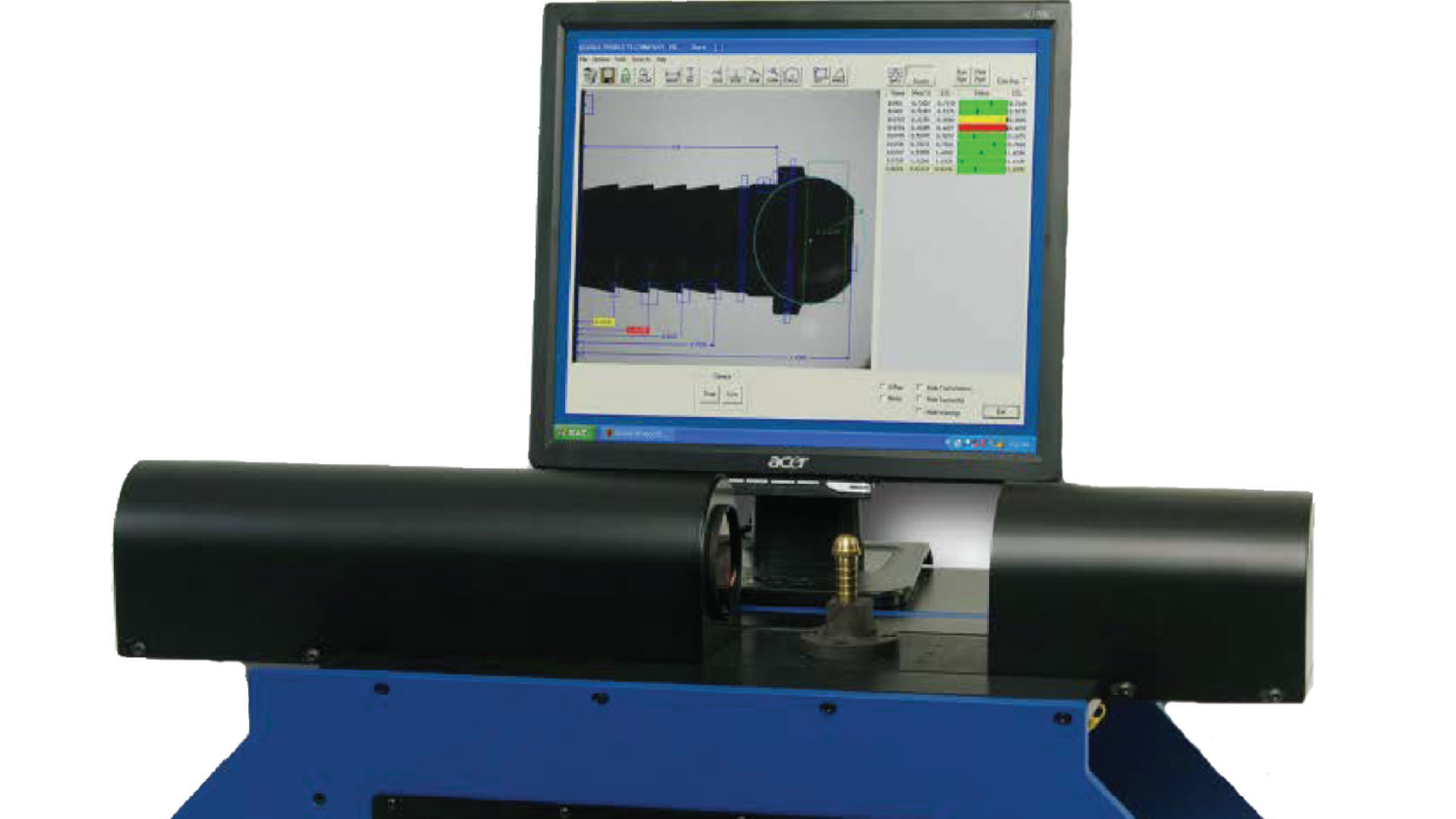

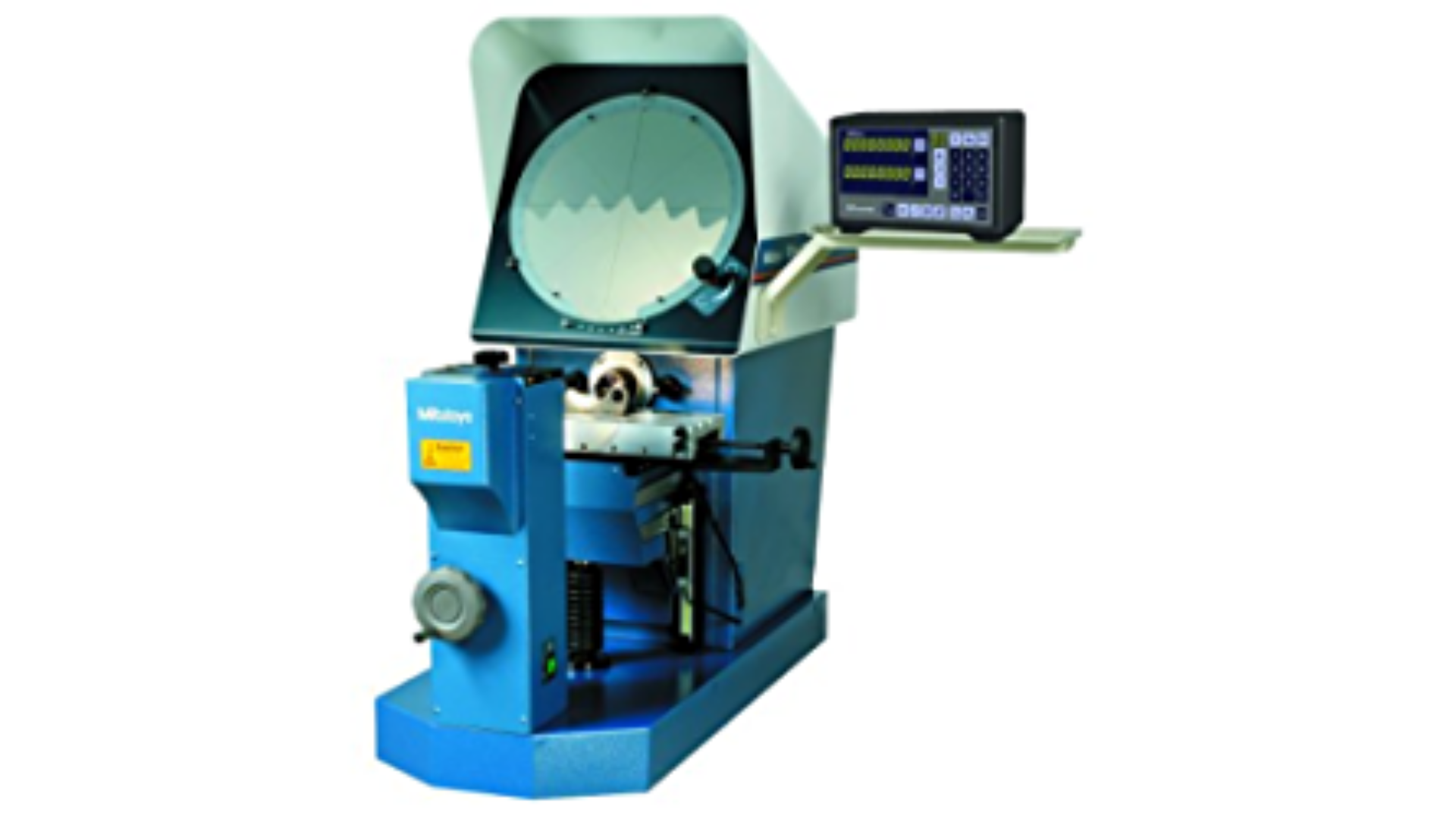

Our goal is to give you the best quality product while keeping costs at a minimum. To accomplish this we have instituted a First Piece-Last Piece Inspection System. A full print layout and part inspection is documented at the point of set-up and a last part. In process inspection is done frequently. We also maintain inspection and material certification documentation for customer part. The Oasis Inspection System features: Instant Measurements, Simultaneous measurements in multiple dimensions, Accurate measurements to 0.0001 inches, and automatic inspection reporting. The Mitutoyo Optical Comparator features: • Bench-top model that uses horizontal optical system. • Suitable for thread pitch measurements—blurred or distorted images will not be produced when workpiece is angled.• 14" (356mm) diameter vernier protractor screen with solid line cross-hairs for easy alignment.• The PH-A14’s generous X, Y workstage travel (8”x 4”) provides users with ample range to cover application needs.

Click to see Keyence IM-8000 capabilities

Gallery

DAVE KARMAS

President

Borderline Swiss CNC has been in business since 2013 and I have worked in the manufacturing industry for over forty years. The majority of that time has been spent in CNC turning and CNC Swiss machining, providing scheduling, programming, maintenance and quality control for a large machining company. As a supervisor, I played a key role in implementing ISO certification and I am certified as an internal auditor. With my solid background in manufacturing, I do my best to provide you with the highest quality parts at competitive prices.ABOUT

Our company is based on the belief that our customers' needs are of the utmost importance. Our entire team is committed to meeting those needs. As a result, a high percentage of our business is from repeat customers and referrals. We would welcome the opportunity to earn your trust and deliver you the best service in the industry.

Who We Are

Borderline Swiss is a family owned and operated CNC Swiss turning company on the border of Northern Illinois and Southern Wisconsin. Our goal is to provide our customers with not just the parts they need, but parts of the highest quality. Using precision machining we've created custom quality parts for a variety of different industries including automotive, firearms, industrial, and fluid control.

Contact Info

TESTIMONIALS

Read what people have to say about us!

We have been purchasing CNC lathe parts from Dave at Borderline Swiss since he opened his doors and have been quite pleased with both his delivery and quality of products...He has always been able to help on our sometimes unreasonable delivery requests and has not let us down, ever. He does exactly what he promises to do.

I just wanted to follow up and let you know that we were very impressed with the parts we received last week. The stainless rivets turned out beautiful, and the timing was great. We received these Thursday afternoon, and by Friday morning we were running them at our customer and getting results on par with what we would have expected in a cold headed part. We appreciate your efforts to get these turned around quickly, and the quality is exceptional. Please say thank you to your team for us!

Borderline Swiss produces a beautiful custom push pin for us at a price competitive with Chinese

suppliers. I’ve been happy to bring this job back from China to the U.S. with Borderline Swiss CNC.

CONTACT US

Need a quote? Please fill out the form below to be added to our customer list.